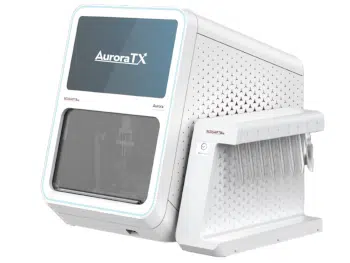

ARC® 305

ARC® 305

The Accelerating Rate Calorimeter (ARC® 305) is designed to safety measure the amount and rate of heat release during the processing or storage of chemicals.

Infos / Datasheet

This method enables the description of isothermal and adiabatic test procedures and is used to detect thermally induced exothermic decomposition reactions. The standard procedure is the Heat-Wait-Search (HWS) method.

The temperature and pressure of exothermic reactions are measured simultaneously in this closed system. The resulting information helps engineers and scientists identify potential hazards. And are focused on key elements of process safety design including emergency relief systems, effluent handling, process optimization, and thermal stability. By analyzing the gaseous reaction products, a better understanding of the reaction mechanism can be achieved.

User safety is a key objective in the design of model 305. The user is protected by a series of safety systems that are completely independent of the control system. These safety systems work to project the user in the event that the primary control system fails. The computer-controlled ARC® 305 is characterized by an easy-to-understand and easy-to-use graphical user interface.

Functional principle:

In the adiabatic calorimeter, the sample material is heated in a fixed volume without releasing energy to the environment until the exothermic reaction starts. The pressure and temperature are recorded during the tempering process. This enables the quantitative determination of enthalpy and pressure changes.

The energy release from chemical reactions is a point of focus in chemical research and other industries. When energy is generated by a thermally induced chemical reaction and the heat transfer to the outside is smaller than the generated amount, runaway reactions can occur. In the worst case, this can lead to an explosion.

Adiabatic calorimeters are ideal tools for analyzing such scenarios as they simulate the worst case scenario with no heat exchange with the surroundings. The behavior in real large scale chemical reactors can therefore be simulated in the laboratory.

ARC® 305 supports with:

- Thermal Hazard Evaluation

- Pressure Hazard Evaluation

- Thermokinetic Analysis

For further information, please refer to the technical data sheet or the brochure.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Facebook. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)